Hide-Away® Storm Shelter – Our stationary model that can be configured in a variety of shapes and sizes to fit your needs. All of our Hide-Away Storm Shelter models are certified to provide protection from devastating F-5 tornadoes and Active Shooters. Every shelter is also rated for NIJ Level IIIA ballistic protection* (all handgun and shotgun rounds).

↓ Watch Our Videos Learn More ↓

Quitman School District, Arkansas

Storm Shelter Testimonial Video

NSS Safety

Pod Review

Active Shooter / Storm

Shelter Drop Test

Classroom Active Shooter

/ Storm Shelter Tour

School Safe Rooms for Active Shooter and Storm Shelter

The solution to school security we’ve all been looking for …

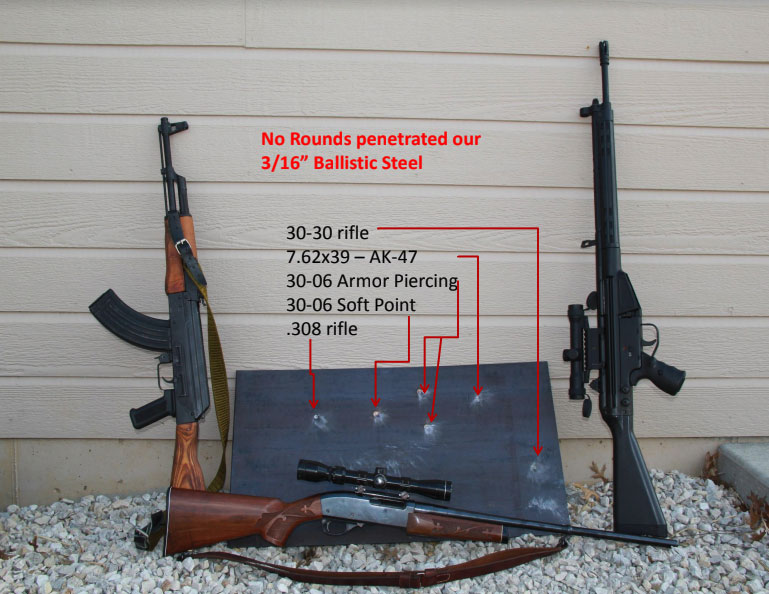

- Provides complete protection, even from military-grade weapons

- Immediate Safety From: Handguns, Shotguns, AK-47’s, AR-15s and IEDs

- Fast, convenient and effective

- Protects an entire classroom – not just a single person

- Does not involve more guns as part of the solution – no armed guards

Key Features For All Active Shooter / Storm Shelter Units

- Certified to withstand F5 tornadoes

- Tested at National Wind Institute (NWI)

- Meets FEMA 321/360 and ICC 500

- Made of 1/4” steel

- 1” locking pins and 1” continuous hinge

- 3/4” diameter grade 5 bolts

- Durable powder coat finish

- Ventilation hoods

- Modular bolt-together design

- Anchors securely to concrete slabs

- Electrical ground stud

- Above-ground shelter – doesn’t flood

- ATSA listed

- Third party engineering certified

Storm shelter's safety features could also protect children at school

Posted: Mar 21, 2013 5:11 PM CDT – Thursday, March 21, 2013 6:11 PM EST – Updated: Mar 22, 2013 4:45 AM CDT – Friday, March 22, 2013 5:45 AM EST

By Laura McCallister, Multimedia Producer – email

By Erika Tallan, Reporter – email

KANSAS CITY, MO (KCTV) –

Since the horrific events of the Sandy Hook tragedy, parents, school officials and government leaders are searching for ways to keep kids safe. An innovative hideaway unit originally designed to be used during severe weather season could be the answer schools have been looking for.

The unit, called Hide-Away, is on display at the Greater Kansas City Home Show as a storm shelter that protects people from the force of an F5 tornado. But it may have a dual purpose of shielding students from a shower of bullets.

“It stands the hair on the back of my neck up when we think about what this could be,” said Mike Vogt, the president, and CEO of Staying Home Corp.

The storm shelter could be the answer schools are hoping for to keep students safe in a crisis, according to Vogt. He and his team wanted to create a storm shelter easily accessible for the elderly.

“The quarter-inch steel is set up where it would prevent anything, including F5 tornado storm damage,” Vogt said. “They take a 20-foot-long air cannon and shoot 2x4s at the shelter that weigh 15 pounds and they shoot them at 100 mph at the sides.”

The design tackles two obstacles in the storm shelter industry. It is an above ground shelter made of a quarter-inch steel, so digging in places with ground water or rock issues is no longer a problem. Also, it hardly takes up any space in a home and can be anchored to the floor.

Then he and his team got the idea to make the shelter bulletproof.

“The fact these two came together was just a fluke in the past couple months in light of the Sandy Hook shootings,” he said.

It expands to 21-square-feet of space, securing up to 15 elementary-aged children in a crisis. Placed side-by-side, a whole class can find safety.

KCTV5’s Erika Tallan found it easy enough for a petite person of her size to roll open and it can be fitted to deploy automatically at the push of a button.

“A superintendent or teacher could issue a simple command, like lockdown, or whatever into a phone, have doors automatically lock, have emergency personnel contacted, have lights come on, all this could occur simultaneously,” Vogt said.

Vogt and his team said there isn’t anything else like it on the market.

“And it’s an answer without guns, without firearms, that we think could be placed around the country. We’re pretty excited about this,” he said.

The company has a patent pending on the idea. It is planning a trip next month to California to introduce the idea at the National School Board Show.

Click here for more on the Home and Garden Show.

Go to stayinghome.com to learn more about the Hide-Away storm shelter.

Hide-Away Shelter / Single Source Document

Staying Home Corporation (SHC) – May 2, 2019

Hide-Away Shelter / Single Source Document

Dennis:

Allow me to begin by thanking you for your interest in our shelters for this application. As you know, there are several elements of our shelter that we believe are not being done by any other manufacturers.

Unique Elements and Traits of the Hide-Away Shelter as manufactured by SHC:

- Our ballistic shelters incorporate MIL-A 46100 Ballistic Steel for the fronts and sides of the shelters. This material is difficult to obtain, and more difficult to work with. Nobody else in this industry makes claim to use this material, though it is the premier bullet proof steel available.

- Our ballistic shelters come with an optional “window” in the door. The window has been tested at Texas Tech to withstand F-5 impact for tornados and also has the same or higher traits as the MIL-A-46100 steel used on the shelter front and side walls.

- Our shelters are the only ballistic designed shelters available that allow the size and configuration (straights, “L” shape, “U” shape, etc.) to be changed in the field. This means a school can enlarge or shrink the size of the shelter in years in which classroom attendance increases or decreases in size.

- Minimum 15/16” diameter solid steel hinge rod running the full height of the door – surrounded by 1 ¾” diameter steel hinges, 3/8” thick. This assures the ability to always open the door as it the hinge is simply not able to be damaged by impact to the degree that it would prevent the door from opening.

- Minimum of 3, 15/16” dia steel door locking bolts

- The door and shelter meet ADA requirements…something we don’t believe other providers have.

It is my hope this provides more than enough uniqueness to make a single source purchase viable. Please advise if there is any further info you require or any other way I can assist. We greatly appreciate your interest and hope to be able to provide what is simply the best dual purpose shelter available.

Best regards,

Michael D. Vogt

Michael D. Vogt, President

Staying Home Corp.

Prefabricated Tornado & Ballistic Storm Shelters Specification

PART 1 GENERAL

1.1 PRODUCT SUMMARY:

- Prefabricated steel FEMA 320 / 361 Fixed structure ballistic/tornado shelter.

1.2 REFERENCES:

Shelter shall be designed, manufactured and installed in accordance with the following standards:

- FEMA 320 Taking Shelter From the Storm

- FEMA 361 Design and Construction for Community Safe Rooms

- ICC 500 Standard for Design and Construction of Storm Shelters

- American Welding Society (AWS)

- ADA Accessibility Guidelines (ADAAG)

- International Building Code (IBC)

- American Society for Testing Materials (ASTM)

- ANSI A117.1

- National Electrical Code (NEC) (When optional electrical items are required)

- Texas Tech University Test for Debris impact

- Certified Structural PE design approval.

- Steel manufactured to MIL-DTL-46100D / With a (BHN) hardness range of 477–534

1.3 DESIGN REQUIREMENTS:

- Tornado Shelter: Provide factory prefabricated shelters capable of withstanding the effects of an F5 tornado.

- Tornado Shelter Design Loads: Determine loads based on following minimum requirements:

- Wind Load: 3-second gust of 250 mph (standard).

- Debris impact 2”x4” and weight of 15 LB projectile at 100mph.

- Impact permanent deformation not greater than 3”

- Anchoring bolts at pull out point of 45,000 lb. force.

- Tornado Shelter Concrete Anchoring Criteria:

- Base anchoring points to be secured to a Concrete pad / floor minimum design criteria 4” thick 4000 PSI reinforced concrete.

- Minimum base anchoring points to be at each corner and each side of door with additional anchors as required per manufactures design.

1.4 PERFORMANCE REQUIREMENTS:

- Cooperate with local regulatory agency or authority and provide data as requested by authority having jurisdiction.

- Prefabricated shelters specified herein shall be handicapped accessible in accordance with ICC/ANSI A117.1 and other state and local requirements as applicable.

1.5 SUBMITTALS

- Product Data: Manufacturer’s data sheets on each product to be used, product metals & finishes available upon request.

- Preparation instructions and recommendations.

- Storage and handling requirements and recommendations.

- Manufactures installation instruction methods.

- Shop Drawings: Include plan views, sections, door details, and anchor detail.

- Selection Samples: For each finish product specified, two complete sets of standard color samples “Desert Sand”, and or color charts with full range of optional colors.

- Certificates: Product certificates signed by the testing agency or laboratory and material certifications as required.

- Warranty Documentation: Manufactures standard year limited warranty.

1.6 QUALITY ASSURANCE:

- Manufacturer Qualifications: Company specializing in manufacturing prefabricated shelters with a minimum of twenty years’ experience in manufacturing and fabrication processes. A quality assurance program utilizing an independent third party to test each system design to industry standards.

- Prefabricated Components: Comply with manufacturer’s published literature for products meeting indicated design loads in accordance with state and local requirements as applicable.

- DELIVERY, STORAGE, AND HANDLINGS: Store products in manufacturer’s unopened packaging until ready for installation.

- Protect all components and accessories from corrosion, deformation, damage and deterioration when stored at job site. Keep materials free from dirt and foreign matter.

1.7 PROJECT CONDITIONS:

Maintain environmental conditions (temperature, humidity, and ventilation) within limits recommended by manufacturer for optimum results. Do not install products under environmental conditions outside manufacturer’s absolute limits.

1.8 WARRANTY:

- Manufacturer’s Warranties: Provide manufacturer’s limited warranty on products to be free of defects in materials and workmanship from date of shipment.

- Provide copies of the third party manufacturer’s warrantees on all optional accessory items provided such as, but not limited to, UPS battery backup power, lights, phone, radio.

PART 2 PRODUCTS

2.1 MANUFACTURERS:

- Staying Home Corporation, 1503 Vine Street, PO Box 37, Harrisonville, MO 64701 www.stayinghome.com

Phone: 877-378-4275 / 816-380-2427

- Substitutions: Not permitted

2.2 MATERIALS:

- ¼” Military Grade MIL-A-46100 (D) ballistic armor plating- tested to .30 armor piercing protection

- 1” cold rolled steel slide locks

- 2” x 2”x 3/16” steel tubing

- 1- ¾” OD, 1” ID-DOM Hinges

- 1” dia CRS hinge pins

2.3 STORM SHELTERS SYSTEM DESCRIPTION:

- Prefabricated Hide-Away Storm Shelter, as manufactured by Staying Home Corp.

- Size: Nominal 3 feet 6 inches by 6 feet

- Size: Nominal 3 feet 6 inches by 4 feet.

- Size: Optional custom, _____ by _____.

- Height: Nominal inside height 6 feet 6 inches to 6 feet 4 inches.

- Doors:

- Doors: Two layer reinforced ¼” grade 50 steel plate with 32” minimum opening and height 66” with low overhead signage.

- Frame: Construction ¼” steel with 3/16” and 1/4” reinforcement interior frame.

- Locks: Three interior locks comprised of 1” dia positive latch points.

- Continuous 1- ¾” OD, 1” ID-DOM Hinges

- Tornado shelter door has outside emergency unlocking device

- Finish:

- Standard Color “Desert Sand” powder coating finish.

- Optional custom color as selected by the Architect from optional RAL powder coating color chart.

- Optional Bed-Liner coating “Desert Sand”

- Capacity:

- As determined by code and size of shelter – 3 ft2/ person residential & 5 ft2/ person commercial

- Nominal 3 feet 6 inches by 6 feet shelter. 7 person residential & 4 person for commercial use.

- Nominal 3 feet 6 inches by 4 feet shelter. 4 person residential & 2 person for commercial use.

- Optional features available:

- 115vac – 4”x4” electrical box, power supply by others.

- Fan – power supply by others.

- Phone – land line by others

- Interior Light – Power supply by others.

- Security Camera System with 2-way communication

- Custom order options contact manufacture for pricing

PART 3 EXECUTION

3.1 EXAMINATION

- Examine supporting foundations for compliance with manufacturer’s requirements, including installation tolerances and other conditions affecting performance of supporting members.

- Check installed anchor bolts for accuracy. Verify that bearing surfaces are ready to receive the work.

- Verify the rough-in of required mechanical and electrical services prior to placement of the structure.

3.2 PREPARATION

- If preparation is the responsibility of another installer, notify Architect in writing of deviations from manufacturer’s recommended installation tolerances and conditions.

- Do not proceed with installation until substrates have been properly prepared and deviations from manufacturer’s recommended tolerances are corrected. Prepare surfaces using the methods recommended by the manufacturer for achieving the best result for the substrate under the project conditions. Clean surfaces thoroughly prior to installation.

- Commencement of installation constitutes acceptance of conditions.

3.3 INSTALLATION

- Install in accordance with manufacturer’s instructions & specifications.

- Place on prepared concrete foundations and slabs provided as specified by manufacture.

- Anchor securely in place USING ANCHORS SUPPLIED BY MANUFACTURE.

- Connect optional mechanical equipment as specified.

- Connect optional electrical equipment.

3.4 PROTECTION & DEMONSTRATION

- Protect installed products until completion of project

- Clean and wax all metal surfaces.

- Lightly lubricate all hinge points and clean any excess.

- Demonstration: Installer to demonstrate proper use and deployment method to owner and representatives.

END OF SECTION